From 30,000 Acres to Like New: Rebuilding a 68-Row Air Seeder

Red E

Март 21, 2025

The Red E team completed a comprehensive rebuild of a 68-row 1890 air seeder in Hillsborough, North Dakota. This wasn’t just a repair; it was a complete overhaul of a machine that had planted over 30,000 acres. We’ll detail the process, challenges, and innovative solutions that restored this machine to peak performance.

The Challenge

Our mandate from the customer was to rebuild the entire rear rank of this 1890 air seeder, a 34-row section that handles the majority of the customer’s planting. This machine primarily uses 15-inch row spacing through a split-rank system, and that has been in use since 2005. However, all the years of hard work had finally taken their toll.

Extended Wear System and Genius Seals: The customer had previously installed an extended wear system and Genius seals, which provided years of service. Some of them were still okay. However, it was time for an upgrade.

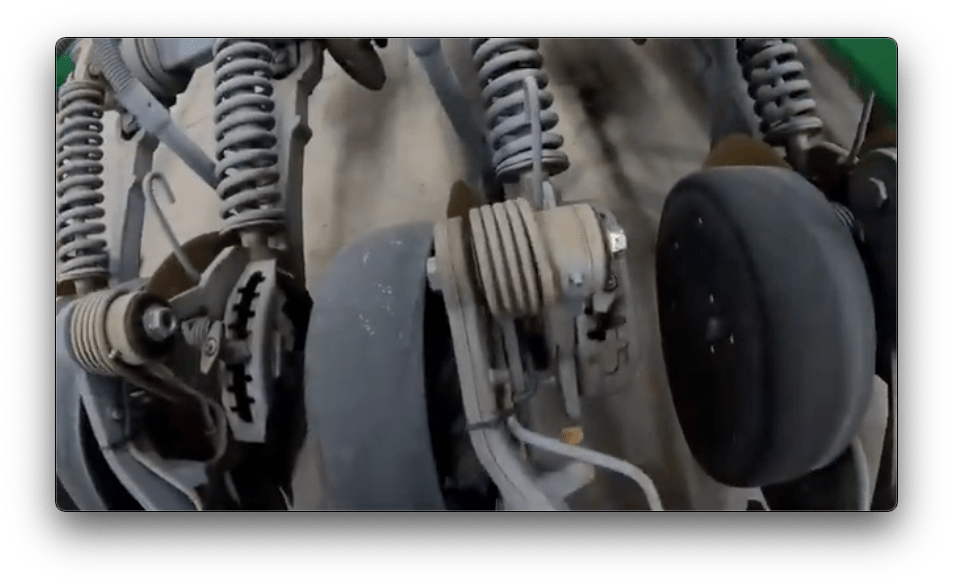

Comprehensive Overhaul: We planned a thorough rebuild, including new handles, springs, closing wheel pivots, shifter plates, seed boots, stabilizers, main opener pins and bushings, discs, and more.

The Process: From Inspection to Installation

We always begin with a thorough inspection to pinpoint every issue, ensuring a meticulous approach.

- Detailed Inspection: We inspected every component and engaged with the customer when there was something additional that was faulty, to create a thorough repair.

- Fixing Bad Components: One common issue was stuck depth adjusters. We used a combination of tools and techniques, including torches and band saws, to free them.

- Finding Solutions: We installed new closing wheel bearing pivot kits with a greaseless design and custom high grease pack bearings, ensuring smooth operation.

- Upgrading Components: We replaced standard parts with heavy-duty alternatives, such as the depth adjuster shifter plates and closing wheel springs, for enhanced durability and performance.

- Aftermarket Solutions: The customer had installed an intelligent ag wireless blockage system, a great alternative due to the switch to a John Deere rate controller drive.

Teamwork & Expertise

Efficient Workflow: Our team worked efficiently, stripping down the machine, installing new components, and ensuring everything was properly torqued.

Problem-Solving: There are times where the traditional ways to fix something don’t work, that’s when we use our expertise to use creative solutions. We encountered this with some broken bolts and seized components.

Results: A Like-New Machine Ready for Seeding

After two days of intensive work, the 34-row rebuild was complete.

- Enhanced Performance: The new components and greaseless bearing design ensured smooth, consistent operation.

- Increased Durability: Heavy-duty parts and meticulous installation mean this machine is ready for many more seasons.

Customer Satisfaction: The customer was thrilled with the results, knowing their air seeder was back to peak condition.

Conclusion

Rebuilding a complex machine like the 1890 air seeder requires expertise, teamwork, and a commitment to quality. In Hillsborough, we demonstrated our ability to tackle any challenge and deliver exceptional results. This project highlights our dedication to providing top-notch repair and maintenance services, ensuring our customers’ equipment performs at its best.

Do you have a similar rebuild project in mind? Contact us today to learn how we can help you keep your equipment running smoothly.

Category: ЗАПЧАСТИ ДЛЯ ПНЕВМОПРИЦЕПОВ